Switching establishes connections between telecommunication network nodes or routes. In the past, switchboard operators manually switched connections so that people were able to communicate through telephone networks. Today, switching technology is highly advances allowing digital voice packets travel between IP addresses within telecommunications networks. Let’s take a look at some of the basics.

Switching Technology Basics

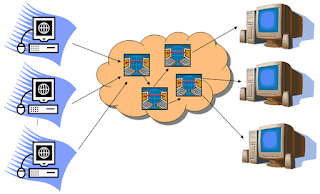

The technology includes local, tandem and transit switches. Telecommunications providers use local switches to support specific areas and tandem switches to connect various switches within a network. Transit switches support long-distance connections. The three main switching types are circuit, packet and message. Here's a little more information about each type.

Learn More About Switching Technology

Working for a communications system company in the USA, we are required to fully understand digital switching technologies. At a local level, we can configure and install an E1 switch for companies that seek to manage internal telecommunications traffic more effectively. Some clients are seeking more secure voice communications through packet encryption. So we need to install an encryption device that secures conversations before the data packets leaves the private networks of that company.

Switching Technology Basics

The technology includes local, tandem and transit switches. Telecommunications providers use local switches to support specific areas and tandem switches to connect various switches within a network. Transit switches support long-distance connections. The three main switching types are circuit, packet and message. Here's a little more information about each type.

- Circuit Switching

- Packet Switching

- Message Switching

Learn More About Switching Technology

Working for a communications system company in the USA, we are required to fully understand digital switching technologies. At a local level, we can configure and install an E1 switch for companies that seek to manage internal telecommunications traffic more effectively. Some clients are seeking more secure voice communications through packet encryption. So we need to install an encryption device that secures conversations before the data packets leaves the private networks of that company.

6:31 PM

Share: